What is a Universal Testing Machine?

The Wikipedia entry for a Universal Testing Machine (UTM) defines it as: “A universal testing machine is used to test the tensile stress and compressive strength of materials. It is named after the fact that it can perform many standard tensile and compression tests on materials, components, and structures.” This is very true, but perhaps overly simplistic. We’ll try to explain some more capabilities of these machines in this post.

Most common are “tensile tester”, “compression tester” and “bend tester”. There are also UTM’s that have been stripped of capabilities or marketed to a specific sector which have led to the development of specialized names such as “texture analyzer” for food, “top load compression tester” for packaging and pipe, and “peel tester” for adhesives, tapes, and labels. Today, a UTM can perform all of these tests and more. A UTM is a great multi-purpose instrument for an R&D lab or QC department. In layman’s terms, here are a few examples of what a UTM can do:

Tensile Test: Clamp a single piece of anything on each of its ends and pull it apart until it breaks. This measures how strong it is (tensile strength) how stretchy it is (elongation), and how stiff it is (tensile modulus).

Compression Test: The exact opposite of a tensile test. This is where you compress an object between two level plates until a certain load or distance has been reached or the product breaks. The typical measurements are the maximum force sustained before breakage (compressive force), or load at displacement (i.e. 55 pounds at 1” compression), or displacement at load (i.e. 0.28” of compression at 20 pounds of force).

Compression Test: The exact opposite of a tensile test. This is where you compress an object between two level plates until a certain load or distance has been reached or the product breaks. The typical measurements are the maximum force sustained before breakage (compressive force), or load at displacement (i.e. 55 pounds at 1” compression), or displacement at load (i.e. 0.28” of compression at 20 pounds of force).

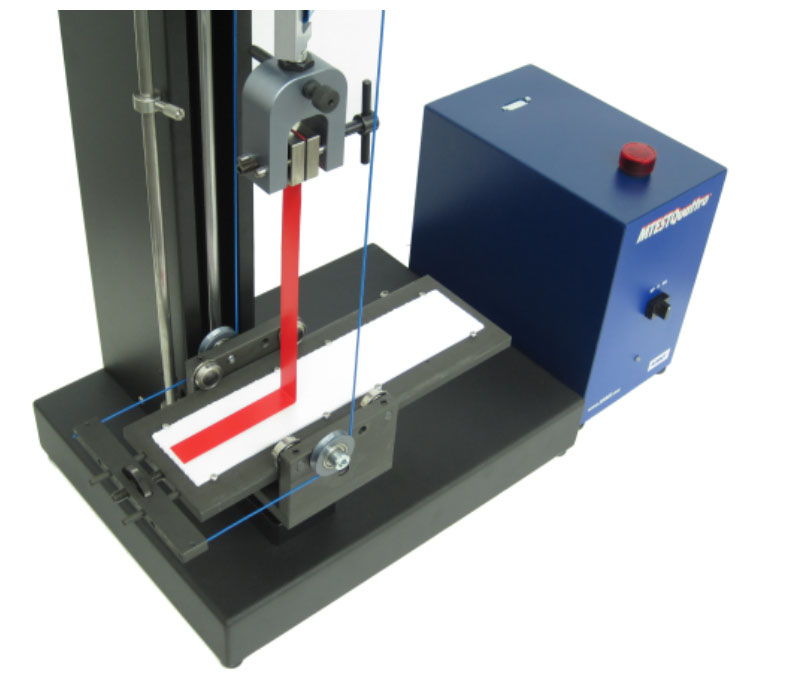

Peel Test: Similar to a tensile test. However, instead of pulling apart a single piece, you pull apart two materials that have been bonded together. In this test, you one clamp holds one material and the other clamp holds the other materials. Then you pull them apart for a few inches. The force is measured up to 1000 times per second during the test and the average of all of the force readings are reported as the “average peel force”.

Bend Test: This is a compression test where you support a length of material by spanning it across two supports on each end. There is nothing supporting the middle portion underneath of it. Then you press down from above directly in the middle of the span of material until the supported material breaks or reaches a specific distance. This test measures how strong the material in flexure (flexural strength) and how stiff it is (flexural modulus).

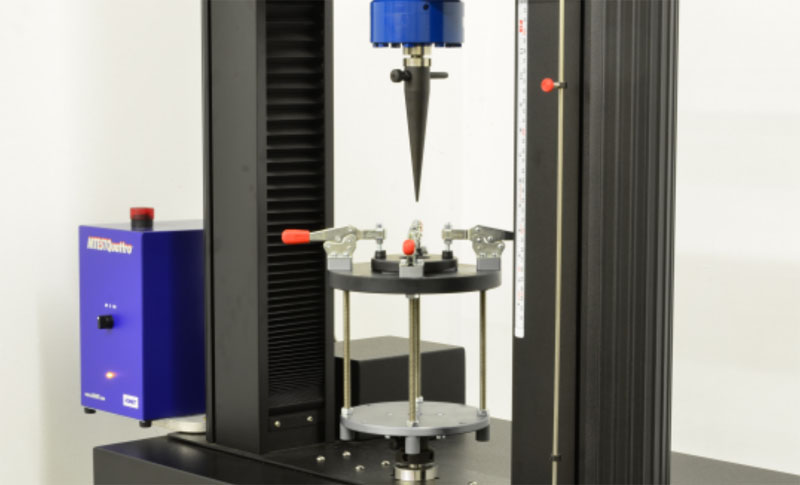

Puncture Test: In this test you secure a circular section of material around its perimeter. Then you come down from above and press the material with a “puncture probe” until the material punctures. The force when the product breaks is called the “puncture resistance”.